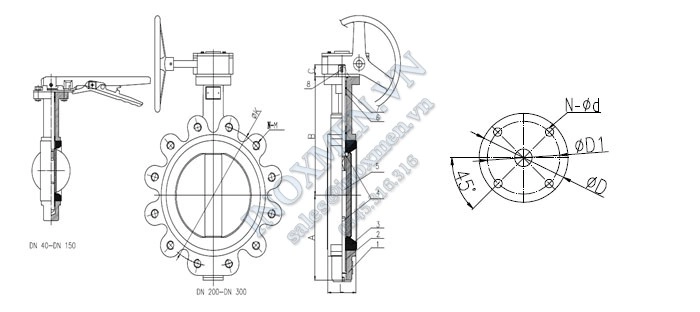

Product introduction

Full PTFE lined lug butterfly valve Size Range: 2~8"(DN50~DN200) Pressure: PN10, PN16, Class125 Body Materials: Cast Iron, Ductile Iron , WCB , Stainless Steel Seat Materials: PTFE Disc Materials: DI/WCB/CF8/CF8M +PTFE lined Stem Materials: SS416, SS304, SS316 End Connection: Lug Operate: Manual, Worm gear, Pneumatic, Electric-Motorized Disc type: One stem no-pin, Double stem no-pin. | ||||||||||||

| ||||||||||||

| L | ANSI 150B | DIN PN 10 | DIN PN 16 | JIS 10K | ISO 5211 | Top Flange | ||||||

| øK | N-M | øK | N-M | øK | N-M | øK | N-M | øD | øD1 | N-ød | ||

| 33 | 98.5 | 4-1/2"-13UNC-2B | 110 | 4-M16 | 110 | 4-M16 | 105 | 4-M16 | 65 | 50 | 4-ø8 | F05 |

| 43 | 120.6 | 4-5/8"-11UNC-2B | 125 | 4-M16 | 125 | 4-M16 | 120 | 4-M16 | 65 | 50 | 4-ø8 | F05 |

| 46 | 139.7 | 4-5/8"-11UNC-2B | 145 | 4-M16 | 145 | 4-M16 | 140 | 4-M16 | 65 | 50 | 4-ø8 | F05 |

| 46 | 152.4 | 4-5/8"-11UNC-2B | 160 | 8-M16 | 160 | 8-M16 | 150 | 8-M16 | 65 | 50 | 4-ø8 | F05 |

| 52 | 190.5 | 8-5/8"-11UNC-2B | 180 | 8-M16 | 180 | 8-M16 | 175 | 8-M16 | 90 | 70 | 4-ø10 | F07 |

| 56 | 215.9 | 8-3/4"-10UNC-2B | 210 | 8-M16 | 210 | 8-M16 | 210 | 8-M20 | 90 | 70 | 4-ø10 | F07 |

| 56 | 241.3 | 8-3/4"-10UNC-2B | 240 | 8-M20 | 240 | 8-M20 | 240 | 8-M20 | 90 | 70 | 4-ø10 | F07 |

| 60 | 298.4 | 8-3/4"-10UNC-2B | 295 | 8-M20 | 295 | 12-M20 | 290 | 12-M20 | 125 | 102 | 4-ø12 | F10 |

| 68 | 361.9 | 12-7/8"-9UNC-2B | 350 | 12-M20 | 355 | 12-M24 | 355 | 12-M22 | 125 | 102 | 4-ø12 | F10 |

| 78 | 431.8 | 12-7/8"-9UNC-2B | 400 | 12-M20 | 410 | 12-M24 | 400 | 16-M22 | 125 | 102 | 4-ø12 | F10 |

Full PTFE lined lug butterfly valve Features Single Eccentric Disc-Shaft Anti-Blow Out Stem Bi-Directional Fire safe Design Low Friction Body Seat Zero Leakage | ||||||||||||

Adoptive Standards Valve Design: API 609, MSS SP-67 Face To Face: API 609, MSS SP-67, DIN3202, BS EN558-1 Pressure Test: API 598 Flange Drilling: ANSI B16.1 class125, BS4504 PN10/PN16, DIN2501 PN10/PN16 Top Flange: ISO5211 | ||||||||||||

Standard Test Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test. Seat Test: 1.1 times the working pressure with water. Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc. Special Test: On request, any other test can be carried out according to special instruction by client. | ||||||||||||

| Application | ||||||||||||

● Water Treatment Plant ● Drilling Rigs ● Paper Industry ● Gas Plant ● Sugar Industry ● Cooling Water Circulation | ● Breweries ● Heating & Air Conditioning ● Chemical Industry ● Pneumatic Conveyors ● Waste Effluent Treatment Plant ● Compressed Air | |||||||||||

LƯU Ý:

Sản phẩm Van bướm tay kẹp bọc kín TEFLON PTFE nối lug Inox Men được phát triển liên tục, thông tin có thể thay mà không kịp thời thông báo đến Qúy khách hàng!

Đánh giá sản phẩm của chúng tôi